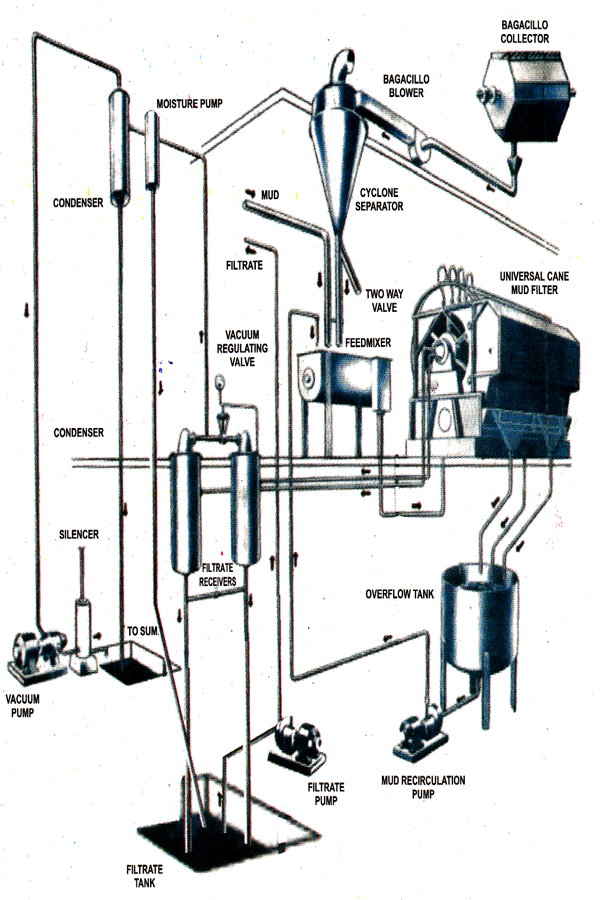

Cane Mud Vacuum Filter :

The Universal Cane Mud Vacuum Filter is a heavy duty filter engineered and designed to increase efficiency and savings by greatly increasing the amount of recovered sugar. Hundreds of satisfied mill owners are the best proof that a filter station literally pays for itself through this high sucrose recovery as well as adding further savings in evaporation costs and reduced maintenance. The Filter has proven its worth for several decades. Because of its efficient and economic operating advantage, cane sugar factories all over the world continues to adopt the Vacuum Filter method of handling cane mud as “standard practice”.

Size Manufactured By Us :

The Vacuum Filter is manufactured in different sizes to suit specific requirement from 8’ dia x 8’ long to 14’ dia x 36’ long.

Sizes & Capacity Detail Of Filter Systems :

| FILTER DRUM AREA | |||

| Diameter | Length | Sq. feet | Diameter Length Sq. feet Sq. meter |

| 8’-0” (2438mm) | 8’-0” (2438mm) | 200 | 18.59 |

| 8’-0” (2438mm) | 12’-0” (3658mm) | 301 | 27.97 |

| 8’-0” (2438mm) | 16’-0” (4877mm) | 402 | 37.38 |

| 10’-0” (3048mm) | 20’-0” (6096mm) | 628 | 58.42 |

| 12’-0” (3658mm) | 20’-0” (6096mm) | 754 | 70.11 |

| 12’-0” (3658mm) | 22’-0” (6706mm) | 830 | 77.12 |

| 12’-0” (3658mm) | 24’-0” (7315mm) | 905 | 84.13 |

| 14’-0” (2467mm) | 18’-0” (5486mm) | 792 | 73.62 |

| 14’-0” (2467mm) | 20-0” (6096mm) | 880 | 81.79 |

| 14’-0” (2467mm) | 24’-0” (7315mm) | 1056 | 98.16 |

| 14’-0” (2467mm) | 26’-0” (7925mm) | 1144 | 106.33 |

| 14’-0” (2467mm) | 28’-0” (8534mm) | 1232 | 114.52 |

| 14’-0” (2467mm) | 30’-0” (9144mm) | 1320 | 122.69 |

| 14’-0” (2467mm) | 32’-0” (9754mm) | 1408 | 130.87 |

| 14’-0” (2467mm) | 34’-0” (10363mm) | 1496 | 139.05 |

| 14’-0” (2467mm) | 36’-0” (10973mm) | 1584 | 147.23 |

Salient Features :

• To reduce maintenance cost we select non corrosive like, Stainless Steel 304 grade material used for the drum shell, division and end strips, internal piping, filtrate valve

and perforate screens, Stainless Steel corrugated decking fixed with stainless rivets or polypropylene grids, as standard material.

• Internal piping and juice inlets spaced across the full length of the Filter.

• High efficient displacement washing process and nozzle spray design, reducing pol losses to a minimum.

• Continuous automatic operation.

• All Filters include these accessories as standard equipment.

• Cover leaning shower pipe with brass nozzles located at the back side of the filter for periodic washing of the filter drum.

• Wash water strainer.

• Automatic lubrication system.

• Repair kit and installation tools.

• Totally enclosed motors.

Bagacillo Arrangement

Filtrator Receiver

Condensors

In systems involving heat transfer, a condenser is a device or unit used to condense a substance from its gaseous to its liquid state, typically by cooling it. In so doing, the latent heat is given up by the substance, and will transfer to the condenser coolant. Condensers are typically heat exchangers which have various designs and come in many sizes ranging from rather small (hand-held) to very large industrial-scale units used in plant processes. For example, a refrigerator uses a condenser to get rid of heat extracted from the interior of the unit to the outside air. Condensers are used in air conditioning, industrial chemical processes such as distillation, steam power plants and other heat-exchange systems. Use of cooling water or surrounding air as the coolant is common in many condensers.

INT Saperator

Belt Conveyor

Filter Reciving Tank

Feed Mixture(Mud Mixture)

Interconnecting Pipeline

Mud Over Flow Tank

Pumps